Everyone loves homemade apple juice, because it is not only tasty, but also healthy. But where to get real apple juice, without chemicals and preservatives, in stores it can hardly be bought. The only solution to this problem is to make homemade apple juice by yourself.. However, in order to get it, you need to overcome a number of small difficulties. To make your job easier, you'll need an apple grinder and a juicer. It is thanks to the shredder that you will spend a minimum of time and effort on getting homemade apple juice. In this article we will look at how to make homemade grinder for apples.

Table of contents

The advantages of a homemade grinder

The grinder can be purchased in a store or on the Internet, but the real craftsmen will make this unit themselves and spend a minimum of money. The chopper is necessary for crushing apples into small pieces, if the apple is well crushed, then it is easier to pressand the juice yield is much greater. It is believed that the more homogeneous the mass after grinding, the easier it will be to squeeze out the juice.

What are the advantages of an apple crusher:

- For processing a large number of apples it will take a minimum of time.

- Virtually no waste. The whole juice is squeezed out of the apples and a small amount of oilcake remains.

- To design a home chopper, you will need minimum cost.

- All is reduced to a minimum physical effort.

- Recycling small batches of applesthat is most suitable for household.

- Reliability and practicality equipment.

- In case of malfunctions, repair is carried out independentlythat saves money again.

In order to independently design an apple chopper, you will need a basic set of tools that each owner has. In addition to tools, you also need materials, if they are not in the household, then you need to make a purchase.

Making a grinder for apples with their own hands, drawing and diagrams

Grinders can be of different types, some are metal, others are wooden, and others combine in themselves those and other materials. But the main thing is not what the crusher is made of, but how it works.

- Wood Chopper for Apples

- Metal grinder for apples

- Combined Apple Chopper

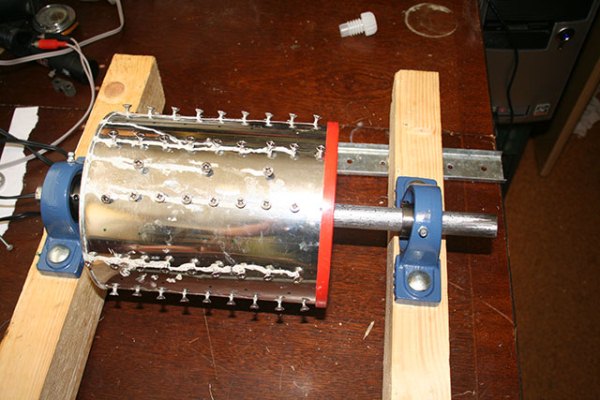

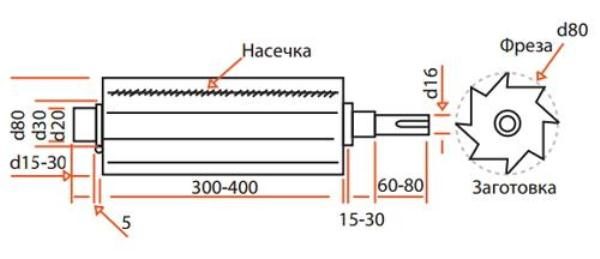

First we need a sheet of metal, stainless steel, d 80 mm. From this blank we make steps for the shaft exit and under the bearings. Works are carried out on the lathe.

Next we need a milling machine to make a gear shaft. As shown in the drawing, we remove 8 faces. To enhance the crushing effect, we take a grinder and make triangular notches along the entire length of the teeth..

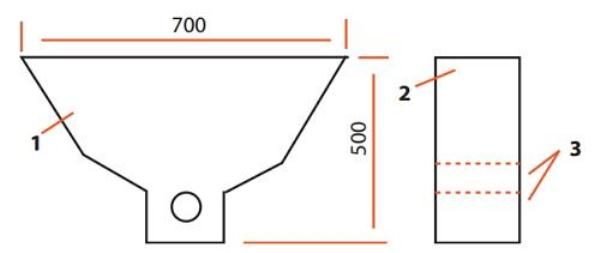

As a body, you can use a washing machine,namely the outer part of it. The washing machine should be a vertical load of stainless steel with a wall thickness of 1.5-2 mm. After we cut it into four parts and get 2 end and 2 side parts. We put all parts together, making a box, and weld it. Before finishing the welding of the side parts, below we bend a little sheet metal, making a small gap between the working shaft and the grinder wall.

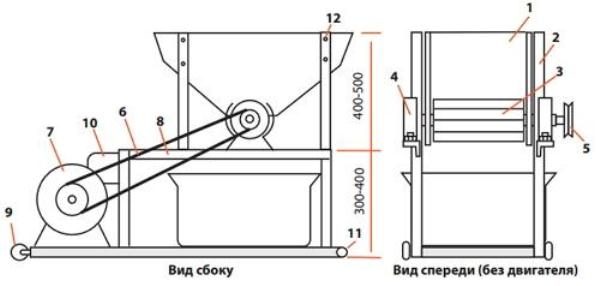

To make the shaft rotate smoothly and be well fixed, we use the usual bearing assemblies that are present in the circulars. From the corners we cook support frame. The base of the machine is made of wood. The board base is located at the bottom, because containers are placed on it for receiving the outgoing mass from the chopper.

To create a control unit, we use a special control gear.This is basically a button that is responsible for switching on and off. The belt is tightened by fixing with a special bolt for clamping and by moving the body along the guides. It is necessary to fasten the handle and rollers to the frame, which increase the comfort of using the device and allow you to transport the chopper to any place on your own.

The crusher body is attached to the upper corners of the frame, by means of bolts, which allows to eliminate its bending under pressure, because apples have their own weight. To reduce splashing, use a wide basin, and make the frame low. The electric motor is placed on the side so that no liquid gets on it.

1 - body, 2 - stiffness corner, 3 - working shaft, 4 - bearing bushings, 5 - belt drive pulley, 6 - belt, 7 - electric motor, 8 - frame, 9 - rollers, 10 - control unit, 11 - transport handle , 12 - housing mounting bolts with stiffening corners

Such a crusher, made by own hands, practically does not differ from the factory one, by virtue of its performance and technicality. In order not to buy a motor, you can use the motor from an old and unnecessary washing machine or other equipment. Electric motor powered chopper, used to crush apples not only for juice, but also for wine. This crusher is always useful in the economy. After passing one through a crusher, even the apples of the hardest varieties turn into a monotonous mass, which can be loaded under a press and squeeze the juice.

Apple shredder care

If you made a chopper for apples with your own hands, then it will be easier to take care of them. The most important rule is cleanliness. Wash the unit thoroughly after each use.. Even all hard-to-reach places should be washed and cleaned. There should be no apples, because their remnants can start to blossom, and when the machine is started up again, it will fall into the mix, and then into the juice, which will lead to its rapid deterioration.

Do not throw a shredder outside in the rain. Moisture will not only lead to rusting of the metal, but also damage to the engine. If your crusher is made of wood, then moisture is also not recommended for her.. After each work, turn off the chopper from the outlet, wash it well and hide it in the room.

Conclusion

In summer and winter to enjoy delicious apple juice, it is enough to make a homemade chopper and squeeze out the juice. Making a crusher for apples is very simple and fast, plus you will spend a minimum of money. Handy materials, old washing machine and you already have your own chopper for apples. With this device you can chop not only apples, but also pears and other fruits. The grinder for apples will become just an irreplaceable thing in the house, make only a little effort and your labors will be rewarded.