Apple trees periodically present amateur gardeners with such a large-scale crop that there is no place to put excess fruit. In addition to jam and compotes, there is one more variant of fruit processing - juice. But many are not associated with this type of blanks due to the high complexity of the process. Ordinary household juicers simply can not cope with a large amount of raw materials, and not everyone is ready to buy a professional machine for the season. But there is a great option - quickly and efficiently squeeze the juice from apples on the press made with your own hands.

Table of contents

What materials will be required

To independently make a standard press does not require special skills and drawings. Measure, saw off rail, hammer a nail or tighten the nut if you wish, everyone can. It is not necessary to own a welding machine, any design can be reproduced in a wooden version using ordinary garden tools.

To make a home press from tools, you will need a hacksaw for wood and metal (or a grinder), a welding machine, screwdrivers, pliers, a hammer. As for the materials, the following are mainly used:

- metal channel;

- wooden bars, slats, boards;

- screws, bolts and nuts;

- tank or barrel, stainless steel sheet;

- Bench screw and nut, valve, threaded rod or jack - depending on the selected design;

- durable fabric with good drainage properties for bags under the apples: calico, cotton, jute sacking, flax.

Types of structures: diagrams and drawings

The main thing in the press - a solid foundation and working mechanism.

The principle of operation of the apparatus:

- in layers through drainage grates fit prepared raw material for spinning (shredded apples) in fabric bags;

- by mechanism top pressure comes down and crushes the juice.

A good press squeezes 65-70% of the juice, leaving the cake almost dry. Make this do-it-yourself is quite real.

The designs of the home-made press differ according to the principle of operation of the main mechanism:

- Screw.

- Jack-based: mechanical and hydraulic.

- Combined.

- Screw (worm) press

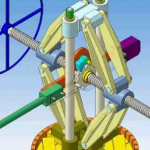

- Screw press layout

- Mechanical press layout

- Hydraulic Press

- Hydraulic Press Scheme

- Combined press

In the bulk of the structures, the pressure is on top, but in the combined version, compression goes in two directions: with a screw mechanism on top and a hydraulic jack at the bottom.

Juice press consists of the following parts:

- steady bed frame;

- quadrangular or cylindrical body, inside of which there are bags of shredded apples;

- wooden latticesby which bags are shifted so as not to creep away;

- piston gnet, directly exerting pressure on the cake;

- thrust bearing for jack;

- working mechanism: screw with handle, mechanical or hydraulic jack;

- bowl-pan.

The main body can be:

- single perforated: the juice through the holes will flow down the walls and through the bottom into the pan;

- double: a perforated metal cylinder puts on a solid casing slightly larger than the diameter;

- in the form of a solid metal case with one drain hole at the bottom;

- assembled from wooden slats connected by hoops- a barrel.The walls at the same time perform the functions of a drainage grate.

There may not be a shell at all - just a pyramid of wooden lattice frames in a tray with a mouth below, under which a container for juice is substituted.

This design is easily and quickly mounted. For the bottom plate, you can take a piece of the tabletop, for example.

Worm gear or hydraulic jack: what to choose?

The screw (worm) mechanism in the press is implemented as a large screw (threaded axis) with a nut or a mechanical jack. The last option is much simpler - you can buy in the parts store or get out of the trunk of the car, you do not need to search for, customize, grind and weld.

Designs based on hydraulic jack significantly more productive (effort from 1 t), than mechanical, and demand a minimum of labor costs from the person. Bottle hydraulic jacks make it possible to squeeze the juice quickly and in large volumes. They fit comfortably into any design.

Making a press with your own hands

The press needs a steady strong support - bed. The simplest thing is to assemble it from wooden bars with screws. For the manufacture of a metal frame will require a welding machine and channel.

The dimensions of the frame depend on the diameter of the working body or the parameters of drainage grids. Therefore, if the body structure is planned, then you need to prepare the container in advance.

The simplest frame press with a worm gear

Weld resistant construction. A hole for the screw nut is cut in the center of the upper channel (you can use the old bench-type or order from the turners). The nut is welded into the frame.

Then going to wooden drainage gratewhich consists of two layers of slats, perpendicular to each other. The thickness of the rails - not less than 20 mm. You also need to install the stand of the bars.A retainer for the pressure part of the screw is attached to the top board - any metal piece that is suitable in shape (can be put on epoxy glue).

The tray is made of stainless steel sheet., in front of the nose-drain arches. It remains to substitute the pan or other container. The result is a press.

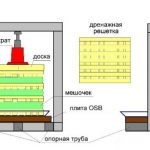

Body hydraulic press for apples

The bed for the hydraulic press is assembled on the same principle as for the screw. As a hull, the easiest way is to take a finished metal or wooden barrel.. At the bottom of the hole is cut and equipped with a drain spout.

If the wooden barrel is not completely sealed - even good. The juice will merge in several directions at once, in the end it will still be in the pan. It is better to put on a plastic casing with a larger diameter so that there are no splashes.

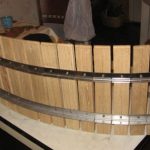

The wooden case can be made independently:

- Will need: several boards of equal size (parquet can be used), two strips of stainless steel and self-tapping screws with a corrosion-resistant coating.

- Boards at the top and bottom are screwed with screws to strips at a distance of about 10 mm.

- Stripes with boards bend in the form of a circle, the ends of the strips are bolted.

- A suitable plastic bowl can be used as a tray. with a carved plum for juice.

- Apple press with wooden rack

- Stripes with boards of the press case are bent in the form of a circle

Another important element - the support for the jack. Usually made of wood: you need to knock down the slats and cut a circle out of the resulting web a little less than the diameter of the working body. You can use the grinder to cut out a support from a stainless steel sheet.

Drainage pads are made as in the description for the screw press.but they are given a round shape.

As a result, the construction should turn out approximately as in the photo.

Raw material preparation

The principle of squeezing apple juice simple - the finer the raw material is chopped, the more the product will be at the output. It is best to use a special chopper (crusher), since it is theoretically possible to finely cut several buckets of apples by hand, but in fact it is difficult to realize.The electric meat grinder for large volumes is also not an option: it roars, howls, heats, as a result it can also burn. You can also make a suitable crusher yourself.

The simplest design homemade crusher

From moisture-proof plywood or stainless steel sheet, a deep hopper is mounted slightly on the cone. Two bars are attached to it for stability from below. A wooden roller (preferably in beech) with spiral-twisted self-tapping screws is cut into the bottom of the tank. As a drum, you can use an ordinary kitchen rolling pin.. The axis of rotation of the roller comes out, a drill is inserted into it and the process begins.

- Metal bunker

- Wooden roller at the bottom of the hopper

Some simply crush the apples in a bucket using a construction mixer.

The process of squeezing the juice from apples at home

After the raw material is prepared, it laid out on cloth bags or wrapped in pieces of cloth on the principle of an envelope. Next, the convolutions are placed in a container, a basket, or simply at the bottom of the structure in layers through drainage grids. Approximately 3-4 packages are placed. Above falls the pressure, the juice flows into the pan.When the push-up process is completed, the pulp is removed, the next batch is loaded.

The remaining oil cake after quality pressure is usually delivered dry and compressed into “pills” (photo 16).

The resulting juice can not only drink fresh, but also to make preparations for the winter:

- pasteurized rolled up juice;

- apple wine several types;

- apple cider.

Apples are a very valuable product.. It is extremely imprudent and wasteful to bury and give the neighbors' pigs excess crop yield. Having built a couple of simple devices, you can quickly and easily process all the fruits. In winter, it will be so pleasant to get healthy and tasty amber drinks from the cellar or fridge!